____________________________________________________________________________

Materials visit

Visiting the modelshop slightly overwhelmed me with the range of materials I could potentially use for every element of my model. I broke up each component of my structure and took note of the different variations of materials I could use for every aspect.

Left and right wing

- Roof

- Plywood (max 2.3mm)

- Balsa wood

- Finn card

- I was recommended these materials at they are malleable.

- Styrofoam

After looking at those materials, I found that it would be quite difficult to create concave shapes with those materials and my time limit. So I found some very useful information sheets that explained the multiple processes I could use to create the Baroque shapes

- Base of floor

- Plywood

- MDF

- Floating technology

- Clear rod 15mm diam

- alluminium tube - 10mm diam

- abs sq tube 9.6 mm

- H column (plastic)

Back path

- Columns

- styrofoam

- plywood

- Floor

- stone

- concrete

- 'balcony edge'

- wire

- wood

- ready made shape

- mesh

- brass cage

Stalls

- Base float

- mdf?

- exterior design

- card

_____________________________________________________________________

During my designing/drawing process I revisited my project proposal because I realised I was losing touch within my base theme of wanting 'to show/create/represent a story/change/process'. I did this because I realised I was designing and aiming for a Baroque facade, which evidently contradicts the area of Canary Wharf and the surrounding middle dock, however I felt it didn't exactly contradict the area strongly enough or show an evident story. It seemed to just add to a better visual aesthetic.

My next idea was to create a facade that used the materials of the buildings that were being gentrified (exterior). The interior would be Baroque style because of its representation of grandeur and exclusivity, in a way this should reflect the 'secrecy, power and exclusivity' behind the City of London and the Canary Wharf region.

I began creating small alcoves in the sides of the walls, which extended from the interior to the exterior wall and created a balcony on the exterior.

I had some issues with trying to create this on sketchup, as sketchup is not the most freeing software for creating curved surfaces. I moved onto Solid works, where I hoped I could create the alcoves and cut out sections of the roof at ease.

I proceeded with creating the roof on solidworks as I knew this software was more suitable for curved surfaces, however I had not anticipated the almighty struggle of using the software. There were many rules involved and it was not as freeing in instructions as sketchup, although sketchup was not as liberating in terms of free flowing curved forms.

I began with creating the interior shape I wanted and then created another model for the exterior, afterwards I combined both methods into one model.

Using solid works was a slight setback because the software was slightly new to me, which meant the form took me almost a week to make.

|

| Exterior |

|

| Interior shapes |

|

| Interior and exterior combined |

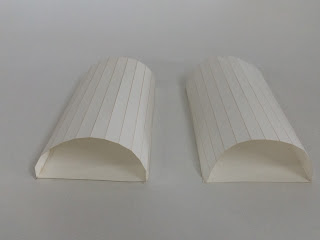

Since this form was time consuming I quickly created more simpler roofs that I could use to determine the scale for my final model and experiment with different materials for the roof. I formed two roofs, one on sketchup and one on solidworks. I discovered that the 3D print from solid works was of a better quality than sketchup. This is where I decided to continue 3D printing from solid works.

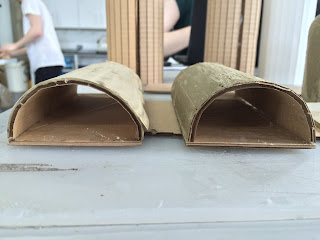

I used a ranged of materials ranging from cardboard, plywood, cardboard and paper and foam. This was an efficient way of testing textures, because I was able to use the laser cutter and do a repetitive process.

The roofs I laser cut ranged from three different heights: a semi circle, an arch just smaller than a semi circle and a raised semi circle. I decided to go with a perfect semi circle in the end as it gave a fuller look to the overall prototype.

I made sure I tested different materials for the roof because curves need a good strength for a base and some materials did not provide enough structure. In the end I decided to use LGC foam board as it kept the curved arch and created good textures, whereas cardboard and paper were not as sturdy.

Throughout this week I extensively tested materials for the roof, as curved surfaces react differently to different materials and I wanted the exact texture and look in the real model, because I felt by being able to create a realistic texture of how I would see it in reality, this really aided me in terms of visualising renders. Having a feel and touching the texture of the building adds a further dimension in really connecting with the building outside of the 'visual' perspective. I didn't want to immerse my model and work in the state of mind of just creating for the visual. An architectural structure is much more than just something to to look at. Overall we are using the space.The space needs to serve you through all the senses, or at least through more than the visual sense.

To get the right texture, I used modelling powder to achieve a concrete/stone texture and then attempted to sand them down.

|

| Carboard and paper, Cardboard |

Foamier created the best texture I wanted for the roof, however it wasn't possible for me to sculpt both the interior and exterior of my solid works model into the foamcore. I could neither use technology to print out the structure using foam core.

Attempting to create separate alcoves to insert into the roof

No comments:

Post a Comment